knife hardness tester|hardness tester file : services G9645 Hardness Tester Simple in design and easy to operate, yet sensitive and accurate. The G9645 Hardness Tester was designed for measuring Rockwell Hardness values of metals and alloys of all kinds, hard or soft, whether flat, round or irregularly shaped. Different indenters and loads can be selected and the hardness values can be measured over three Rockwell scales: . Discover the ultimate guide to steam (autoclave) sterilization for healthcare professionals. Learn the principles, processes, and critical role in patient care.

{plog:ftitle_list}

Autoclaving is a technique that is used to kill the most stubborn microorganisms. It relies on time, temperature, and pressure to generate the most conducive environment for . See more

One example is the Brinell hardness test, used to rate and measure metals too coarse to .

York Saw & Knife uses Rockwell hardness testing on all our customers’ blades as part of our quality-control process. If you require a soft steel alloy in the RC 40 range, you can be sure our techs have tested it to verify that hardness rating before we ship it from the factory. Likewise, if you’ve ordered tough blades with tensile hardness .G9645 Hardness Tester Simple in design and easy to operate, yet sensitive and accurate. The G9645 Hardness Tester was designed for measuring Rockwell Hardness values of metals and alloys of all kinds, hard or soft, whether flat, round or irregularly shaped. Different indenters and loads can be selected and the hardness values can be measured over three Rockwell scales: .

Shop the easy to use Hardness Testing Files from Jantz Supply and quickly test your knife hardness on the Rockwell C Scale. Shop Jantz for all your knifemaking needs. - | / Save up to % Save % Save up to Save Sale Sold out In stock. Order online or call 800-351-8900 Monday .

Since I am new to Hardness testers, I wanted to make sure this is a good system for testing Knife Hardness. Does anyone know if this will do the job? I'm also open to other options for good quality testers. Last edited: Jun 18, 2019. Reactions: .BESS is the measurement scale used by this knife edge tester. Need more information? Call a Product Specialist Monday through Friday, 8 a.m. - 4 p.m. CT Phone U.S.: 1-800-351-8234 Email a Sharpening Specialist [email protected] Emails are answered Monday through Friday The Leeb scale hardness tester is not good for knives, or anything that thin, without careful coupling of the part to a heavier piece. They are intended (and we used them) for thick sections that cannot be moved to the lab, such as pressure vessels, heavy structural steels (thin beam flanges or joist chords/webs are right out), or other .Also, Rockwell hardness test only reveals the surface hardness of a material and not its internal hardness. Apart from the Rockwell hardness number, other qualities of a knife blade that should be considered to determine the quality of a blade are: metal composition, handle construction, grind type, edge bevel, sharpening requirements, handle .

Test your knife hardness on the Rockwell C scale with this testing file set. Files from 40 RC to 65 RC are included in a custom-fitted case, along with complete instructions and a conversion chart for Rockwell to Vickers. These high-quality hardness testing files feature specially curved tips for testing internal slots and grooves as well as . HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

rockwell knife hardness scale chart

rockwell knife hardness rating

koscot test hard nickel

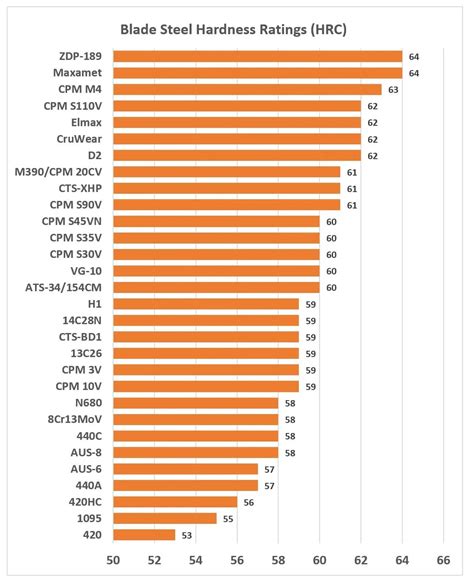

This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): Kitchen knives with lower Rockwell Hardness values, typically in the range of 52-56 HRC (Rockwell C Scale), are considered soft. I'm a little controlling by nature, and the not knowing for sure where my blades are coming in on the hardness scale is killing me. In my research, I've come across several portable versions of rockwell hardness testers that have got me intrigued. My shop is very small, it's tiny actually, and I really don't have room for a bench-top model. Edge-On-Up’s less expensive testers are made for occasional, personal use. They provide resolutions of 5 grams (the “PT50B” model) and 25 grams (the “PT50C” model). Prepping the Tester. The synthetic test wire is housed inside the machined steel test block. The synthetic test wire provides enough length for about 325 tests.

In the knife industry, the Rockwell hardness test is typically used to measure the hardness of the blade at the spine and edge. The Rockwell scale used for knives is typically the C scale, which measures the hardness of hardened steel. To perform the Rockwell hardness test, a diamond or tungsten carbide ball is pressed into the blade with a . Learn what the Rockwell hardness scale means for kitchen knives. The Rockwell scale is the standard for determining a material's hardness. . The Rockwell hardness test is done by measuring the permanent depth created on a material caused by the force of the indenter. A rounded diamond cone indenter is used for steel as it falls under Scale C . The rockwell hardness test measures the knife blade’s ability to resist deformation or indentation under pressure. Different materials used in kitchen knife production can result in varying rockwell hardness ratings. In this section, we will explore the rockwell hardness ratings of various kitchen knife types to help you determine which .

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a . TIP: A Mohs hardness test is one of the most useful tricks that should be in all rockhounds’ playbooks. Check out the best test kits in the article below: . A common knife has a very similar hardness to glass. So, it can also be used to differentiate whether a mineral is softer or harder than 5. A steel file is harder (6-6.5) than a knife .

Rebound testers suck for thin items like knives, and files only ballpark it for you. If you want to actually KNOW what hardness you have, you have to test. R. rob45 Well-Known Member. . My impression about hardness testing is that it is destructive in nature. Meaning that "cleanup" is required, and you're left wondering if you have the same .

In all, the Rockwell hardness of a knife will always be different between high-end knives and low-end knives, for example, an M390 steel knife is a 62HCR compared to 420Hc steel knife which has a 58HCR, it doesn’t necessarily mean that the M390 is better than the 420HC, yes the M390 Is a premium steel with high quality, but it depends on your usage too, for example, both a .As a knife maker, you may have used a hardness tester to perform hardness tests on your knives or saw blades. Ames portable hardness testers are a preferred model for blade makers to perform quick hardness tests. Many knife makers may not have the budget to purchase a new Ames Portable Hardness Tester. Used testers available on eBay and . Don't get me wrong, a hardness tester has its place, but in the overall scheme of making knives, that place is only a small part of a much larger equation. Yes, knowing what procedures (heat treat or otherwise) for a given steel, will give you a specific Rc value is a key piece of information, but it's certainly not the "know all, end all" that .

Hardness and hardness testing is way overplayed. Testing the edge with a file will tell you it hardened, Testing the blade with a brass rod test will tell you if the HT was good. No home smith needs a hardness tester. A lot of full time professional knifemakers have one, but many don't. They are way down on the list of must haves in knifemaking. Rockwell testing can leave a mark on the steel, which is why many makers measure it on a part of the steel that’s concealed by the handle. . 62 RC is very hard so that’s good, it’s important to take the steel material, heat treatment, knife’s purpose, and hardness level into account. When you compare the steel with the hardness, you .The Rockwell Hardness Tester helps create these incredible kitchen sidekicks. When you see a Rockwell Hardness number for a knife, it's like knowing how strong your superhero is – the higher the scale HRC, the tougher the knife. Read about Rockwell Hardness Tester – Today in History, here. 7. Must-Have Premium Dalstrong Knives 1.The Rockwell test of hardness HRc refers to the Rockwell Scale of Hardness, part C. The Rockwell scale is widely used by metallurgists to define just how hard a piece of steel is: the higher the number, the harder the steel. . The hardness of a knife is very important as far as its performance and durability. For instance, a harder steel with .

Shop the HR150A 3R Type Rockwell Hardness Tester at Maritime Knife Supply. Designed for measuring hardness of metal and alloys of all kinds, hard or soft. Simple to operate with accurate testing results. Ideal for schools, laboratories, tool rooms, inspection and heat treatment departments & factories. Includes standard accessories. Free shipping to the United States, .

kpmg numerical test hard

rockwell kitchen knife hardness

The high-pressure steam effectively kills microorganisms, including bacteria, viruses, and sp.

knife hardness tester|hardness tester file